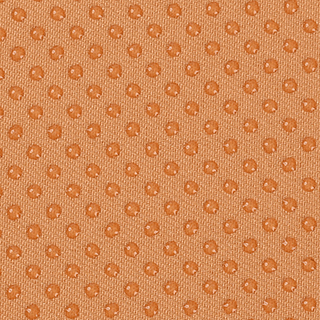

Drip plastic cloth is indeed usually subjected to special surface treatment processes,which are the key to its many excellent properties.

First,the common plastic coating process.On the basis of the cloth,the liquid plastic material is evenly dropped on the surface of the cloth through professional equipment,and then the use of heating,curing and other processes to form a tightly fitted drip plastic layer.This layer of drip plastic layer not only gives the drip plastic fabric a good touch,making it slightly elastic and smooth to touch,but also greatly improves its functionality.For example,the drip plastic cloth used to make infant crawling MATS,after the drip plastic coating,the surface is more soft and skin-friendly,can effectively care for the baby's delicate skin,and enhance the anti-slip performance of the mat to prevent the baby from slipping and injuring himself during crawling.

Second,some drop plastic cloth will use ultraviolet curing process.When the drip plastic coating is not fully cured,ultraviolet light of a specific wavelength is used to irradiate the plastic material to quickly cross-link curing.The advantage of this is to further enhance the stability and wear resistance of the drip plastic layer.Taking outdoor advertising cloth as an example,the drop plastic cloth after ultraviolet curing treatment can remain clear in the outdoor wind and sun for a long time,and the surface pattern and text can be kept clear,and it is not easy to wear and fall off,because the molecular structure of the drop plastic layer is more compact by ultraviolet curing,and the ability to resist external erosion is stronger.

Third,part of the drop plastic cloth will also be integrated into nanotechnology for surface treatment.By adding nanoparticles,such as nano-titanium dioxide,to the drip plastic material,these nanoparticles can be evenly dispersed in the drip plastic layer.On the one hand,the ultraviolet shielding ability of nano-titanium dioxide can improve the protective effect of the drop plastic cloth against ultraviolet rays,and make the weather resistance of the cloth under strong light to a higher level;On the other hand,the presence of nanoparticles can also optimize the self-cleaning performance of the drip plastic cloth,when the water drops on the cloth,it can quickly spread and take away dirt such as dust,so that the drip plastic cloth is always clean and tidy,such as the drip plastic cloth used for outdoor furniture covers is often used this process.

In short,these special surface treatment processes experienced by drip plastic cloth make it play a unique advantage in different fields to meet the needs of many aspects from daily life to industrial production.

If you are looking for related products or have any other questions, you can call our company's sales hotline at 0769-86415161 or 138-2923-0758 at any time. You can also leave us a message below and we will serve you enthusiastically!